All Catalysts • Copper Chromium • High Copper

Copper Chromium

Chromium catalysts have been used for oxidation of volatile organic compounds (VOCs) and carbon monoxide for over 40 years. They are highly active, competitively priced, and tolerant to low to moderate concentrations of sulfur and silicon-containing compounds.

Specifications

| Active component | Copper chromite, CuCr2O4 |

| >5% as Cu₂O₃, >10% as Cr₂O₃, Balance of Al₂O₃ | |

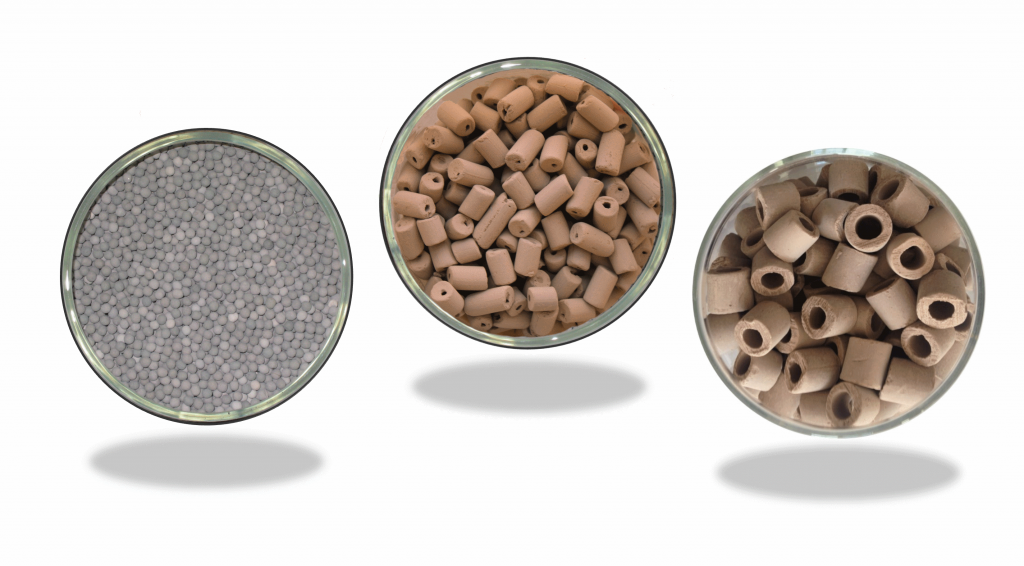

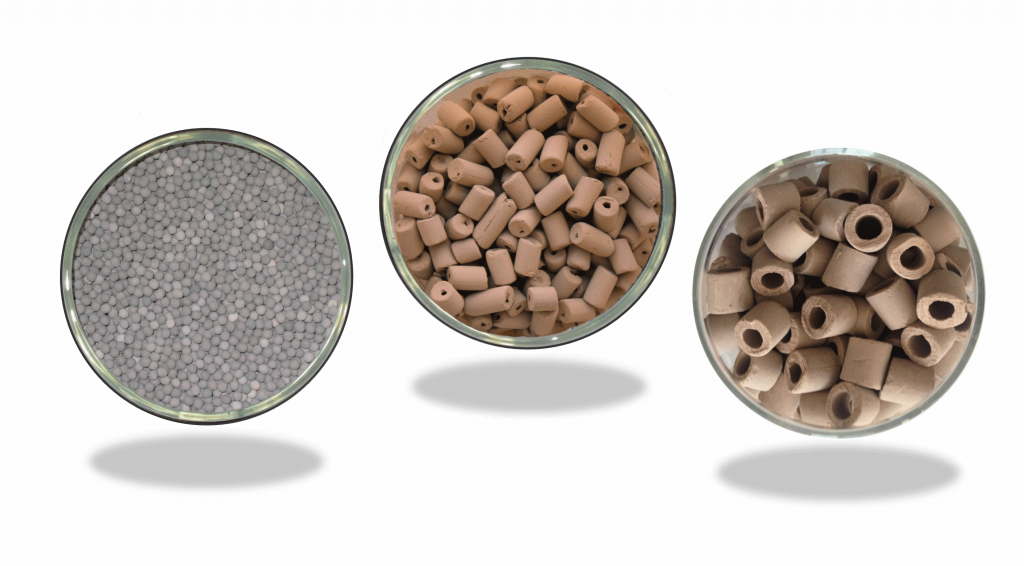

| Common shapes | 3mm (1/8”) spheres, 3-7mm (1/8” – 1/4”) solid cylinders, 10 - 15 mm (3/8”-5/8”) holed cylinders |

| Internal surface area | 150-250 m²/g |

| Bulk density | 0.60 - 1.1 g/cm³, depending on shape and size |

High Copper

The high copper catalyst enhances VOC oxidation at very low temperature and it is often used in combination with the manganese oxide catalyst. It can also be applied in decomposition of ozone emission and ozone-assisted catalytic oxidation of VOCs at room temperature.

Specifications

| Active component | Copper Oxide, CuO |

| Support | Alumina, Al₂O₃ |

| Common shapes | 4 mm (5/32”) extruded cylinders |

| Internal surface area | >30 m²/g |

| Bulk density | 1.6 g/cm³ |