Developed in the 1980s, the manganese oxide catalysts are made via a proprietary thermal activation process that makes the resulting catalyst highly active and resistant to halogens and extreme heat.

Benefits

- Hundreds of commercial applications worldwide in wood, chemical, packaging and other industries

- Reliable and low-maintenance catalysts that combine high activity and many years of service, at a competitive price

- 8+ year service time in wood industry and 5 years and longer in chemical industry and other applications

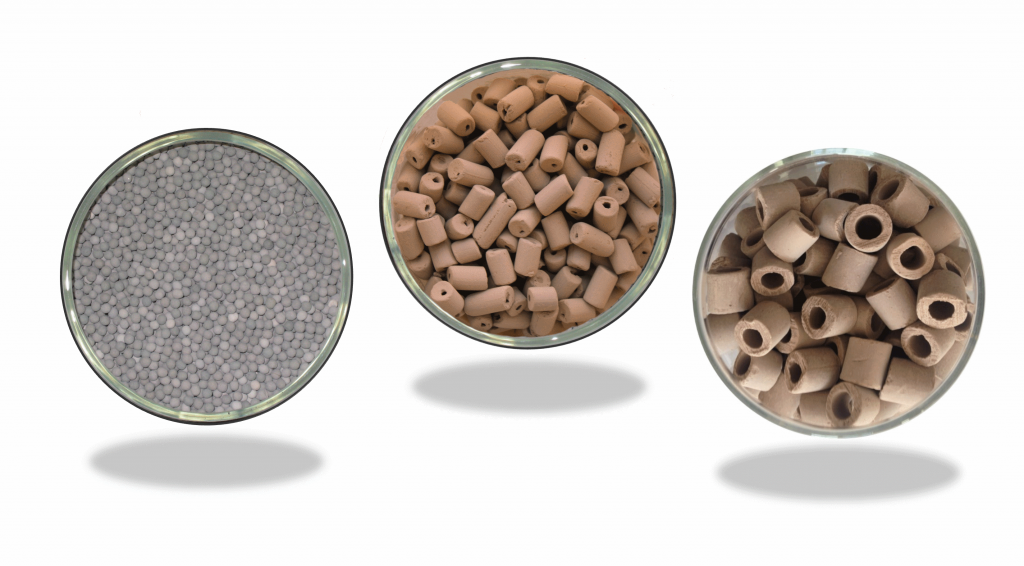

- Produced in a variety of shapes and sizes to fit the requirements of each application

- Particularly effective in regenerative catalytic oxidizers (RCOs) and for converting regenerative thermal oxidizers (RTOs) into RCOs. Smaller size catalysts are used in recuperative oxidizers or afterburners operated with fixed or fluidized beds

- Designed to operate in a wide temperature range, up to 700 °C (~ 1,300°F) long-term, with short excursions up to ~ 900 °C (~ 1,650 °F) withstanding temperature surges during burnouts of RCO ceramic media

- Tolerant of many common catalyst poisons including chlorine, bromine, phosphorus, heavy and alkali and alkaline-earth metals and can be easily regenerated after poisoning via on-line bake out

- Non-hazardous material, safe for handling, loading, unloading, utilization, and disposal in common landfills

Specifications

| Active component | Non-stoichiometric manganese oxide, MnOx |

| Composition | 8-12% as Mn₂O₃, Balance of Al₂O₃ |

| Common shapes | 3mm (1/8”) spheres, 3-7mm (1/8” – 1/4”) solid cylinders, and 10 - 15 mm (3/8”-5/8”) holed cylinders |

| Internal surface area | 25-30 m²/g |

| Bulk density | 0.60 - 1.1 g/cm3, depending on shape and size |