General Services • VOC Technical Services

Our catalyst testing lab serves dozens of US customers operating regenerative and recuperative catalytic oxidizers.

The core test program comprises:

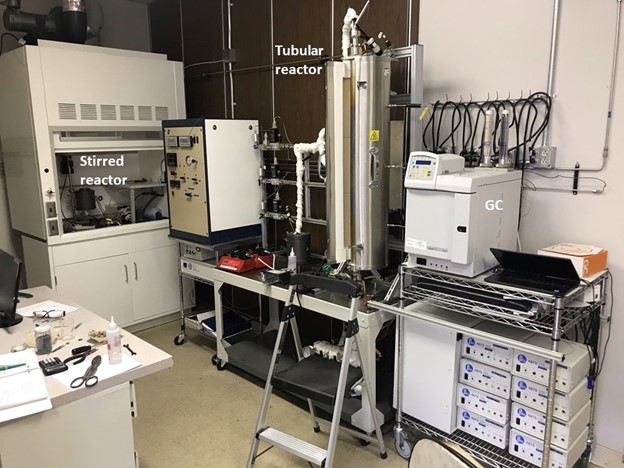

- Activity testing: Our lab is equipped with two reactors for catalyst activity testing. The small size stirred reactor primarily operating with model VOCs enables quick catalyst activity screening. The new tubular reactor built in 2020 is used for testing of relatively large catalyst charge with actual VOCs of interest. Two testing techniques provides versatility of our services. We test any catalyst, including bulk and structured, for any VOCs composition, including very low inlet concentrations and the destruction efficiency approaching 100%. The tests enable accurate prediction of oxidizer performance within the area of inlet parameters often overlapping the experiment.

- Contamination testing: The selected method, Scanning Electron

Microscopy / Energy Dispersive X-Ray Spectrometry (SEM-EDXS)

identifies chemical elements over the surface layer, 1-2 microns deep, and provides for semi-quantitative composition data including catalyst contaminants such as silicon.

- Catalyst regeneration: The lab regeneration via washing or heat treatment determines optimal procedure for restoring the activity of used catalyst that effectively increases the catalyst service time.

- Oxidizer performance evaluation: The oxidizer performance is found directly from tubular reactor tests and indirectly from stirred reactor tests and incorporates basic information about the oxidizer including catalyst quantity, emission air flow rate, operating temperature, etc.